PRODUCT NAME: Olivine Sand

TYPE: Raw Olivine Sand

TIME:2017-11-22

VIEWS:1125

PRODUCT DESCRIPTION:YONAI supplies best olivine from china

As a foundry aggregate, olivine sand is noted for its high fusion point, low uniform thermal expansion and its remarkable ability to resist fracture from thermal shock. Olivine has been famous for years in producing excellent non ferrous castings. Today more foundry men are realizing olivine works equally well in iron, manganese and stainless steel.

The angular olivine grain acts to control the rammed, or squeezed density of a mold. this feature, combined with the favorable coefficient of thermal expansion, usually permits the elimination of organic fillers from molding sand formulations. This angular grain also allows use of finer sands while retaining good permeability. Another advantage of using olivine sand is its industrial hygiene characteristics. Medical research indicates that olivine will not cause silicosis.

Major Advantage of Olivine Sand

1. Thermal conductivity of olivine starts out higher than silica , acting as a heat sink and doesn't increase much thereafter. At high temperatures, it acts as an insulator. This allows a unique control of casting grain structure.

2. The thermal expansion is much lower than silica, therefore, reducing expansion defects without adding costly ingredients. This also enables closer dimensional tolerances of the castings.

3. The angularity of olivine allows the use of finer sand while maintaining good permeability.

4.Olivine's low thermal expansion characteristics results in reduced sand breakdown, less buildup of fines and hence lower sand consumption. Olivine green sand systems can generally operate within wider range of controls and at a lower clay level. This is because the magnesium present in the olivine enhances the bonding properties of the bentonite.

5.Olivine's basic nature makes it particularly unique for pouring manganese steel castings. Since Olivine does not react with manganese , surface defects are substantially reduced.

6.With Olivine, in a nonferrous foundry, a finer grain size can be used to produce a smoother casting while still maintaining good mold permeability. Molds can be rammed of squeezed harder without inducing blows or expansion defects. Therefore ramming is less critical as long as mulling. Clay percentage and compactibility are controlled. The chilling effect of olivine helps to produce smoother surface finish.

7. Olivine in an iron foundry molding sand helps reduce expansion defects without the additional of cellulose or cereal. The low thermal expansion properties of olivine produce a stable mold and therefore help to eliminate centerline shrinkage. Olivine chilling properties are particularly helpful in producing smooth, thin section castings.

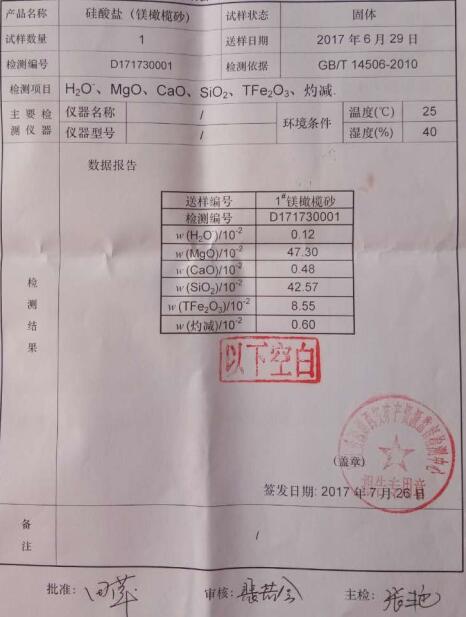

YONAI provide the best olivine sand you can get from china where the MgO content is high and loss on ignition is very low.

YONAI OLIVINE SAND (RAW)

CHEMICAL

CHARACTERISTICS

MgO

SiO2

Al2O3

trFe2O3

CaO

L.O.I

≥ 45%

≥ 42%

≤ 2.5%

5-10%

≤1%

≤ 1.5%

PHYSICAL

CHARACTERISTICS

Refractoriness

>1790℃

Compressive

Strength

2.0-3.0

Mpa

Bulk

Density

2.35-2.42 g/cm3

Size

1-3/1-4/2-5/3-6/4-6 /40-70mesh/70-120mesh

Or upon request